Discover the process of laser metal cutting and how this technology is changing manufacturing as we know it. With the ability to cut through a variety of materials with precision and accuracy, laser metal cutting is quickly becoming the go-to method for manufacturers worldwide. In this article, we discuss the process of laser metal cutting, the benefits of this technology, and how it is changing manufacturing.

What is laser metal cutting?

Laser metal cutting is a process that uses a laser to cut through a variety of materials with precision and accuracy. This process is often used in manufacturing as it can quickly and easily cut through materials such as steel, aluminum, and titanium.

Laser metal cutting has many benefits over traditional methods of cutting, such as milling or drilling, as it is more precise and can be done at a faster speed.

How does laser metal cutting work?

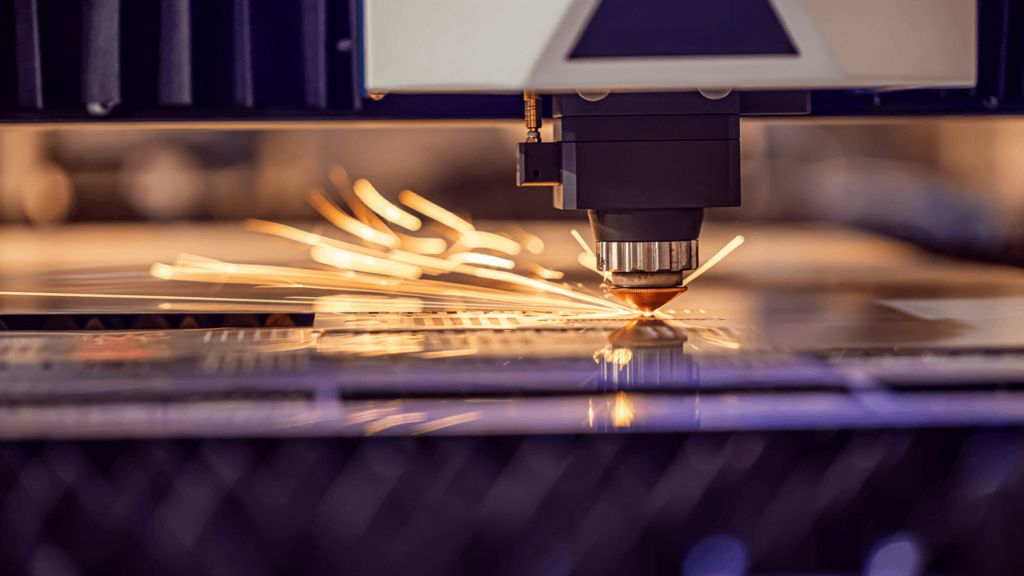

Laser metal cutting works by directing a high-powered laser beam at the material that needs to be cut. The laser beam heats up the material and melts it, allowing the machine to easily cut through it. Laser metal cutting is often used in conjunction with a computer numerical control (CNC) machine to create complex designs and patterns.

The process of laser metal cutting

The process of steel plate cutting generally involves the use of a CNC machine to create the desired shape or design. Laser metal cutting is often used in conjunction with this process to achieve a more precise cut.

The laser beam heats up the material and melts it, allowing the machine to easily cut through it. This process is often used in manufacturing as it can quickly and easily cut through materials such as steel, aluminum, and titanium.

Laser metal cutting has many benefits over traditional methods of cutting, such as milling or drilling, as it is more precise and can be done at a faster speed.

The benefits of laser metal cutting.

Laser metal cutting has many benefits over traditional methods of cutting, such as milling or drilling. Here are some of the benefits of laser metal cutting:

- Laser metal cutting is more precise than traditional methods.

- Laser metal cutting can be done at a faster speed.

- Laser metal cutting produces less waste material.

- Laser metal cutting is more versatile and can be used to cut a variety of materials.

Cost of laser metal cutting

There is no one-size-fits-all answer to this question, as the cost of laser metal cutting will vary depending on a number of factors, such as the type and thickness of the material being cut, the complexity of the design, and the speed of the cutting process. However, laser metal cutting is generally more expensive than traditional methods such as milling or drilling.

Laser metal cutting in the manufacturing industry.

Laser metal cutting is quickly becoming the go-to method for manufacturers worldwide. This is because laser metal cutting has many benefits over traditional methods of manufacturing, such as milling or drilling. With the ability to cut through a variety of materials with precision and accuracy, laser metal cutting is changing the landscape of manufacturing.

The future of laser metal cutting.

The future of laser metal cutting is looking very bright. As the technology continues to evolve, it is becoming more and more popular in the manufacturing industry. With the ability to cut through a variety of materials with precision and accuracy, laser metal cutting is quickly becoming the go-to method for manufacturers worldwide. Thanks to its many benefits, it is safe to say that laser metal cutting is the future of manufacturing.